Infinity group

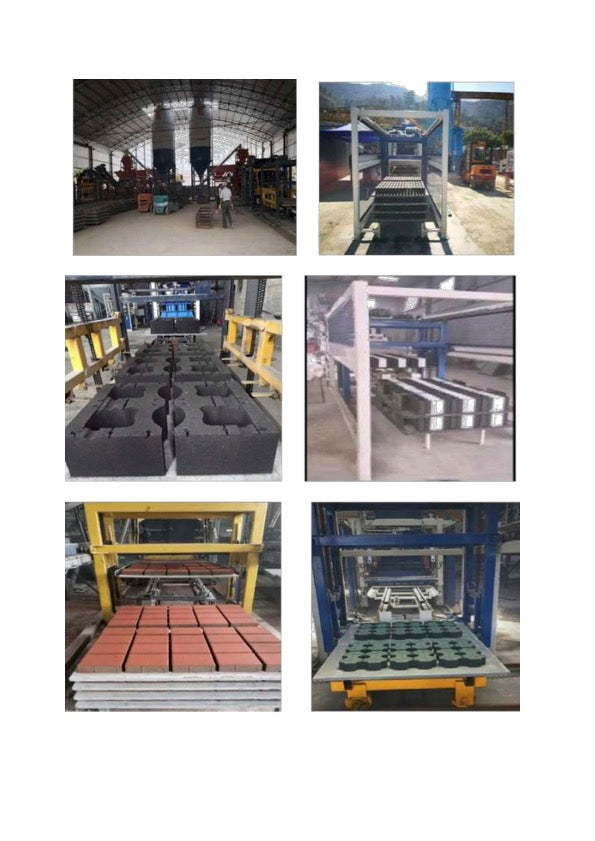

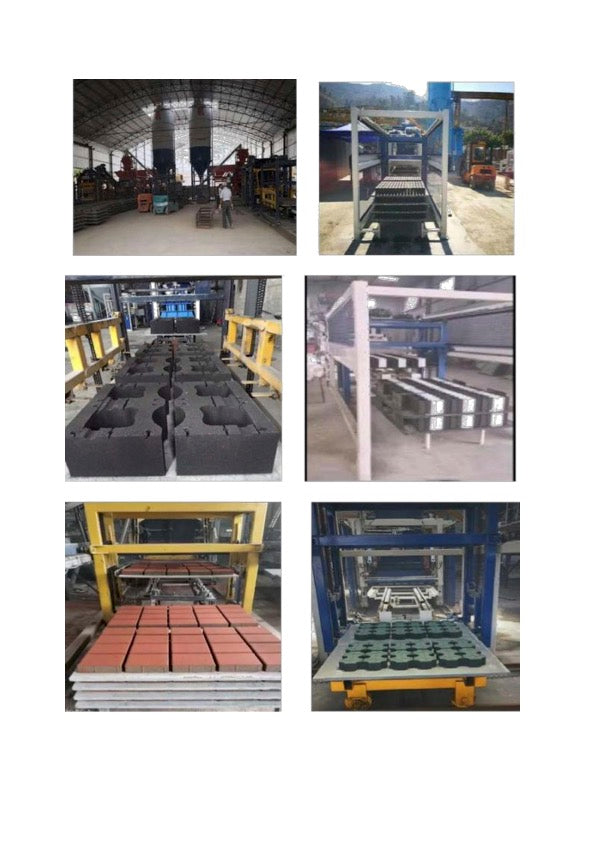

Fully automatic unburned brick machine production line

Fully automatic unburned brick machine production line

Specifications

|

Maximum molding area |

1100×900mm |

Main vibration form |

Hydraulic and vibration |

|

Main body dimensions |

7400× 2300×3000mm |

Vibration frequency |

3800-4500times/sub |

|

Finished product height |

50-200mm |

Electronic control system |

VlGOR |

|

Molding cycle |

15-23 seconds (depending on product shape) |

Total power |

49.85kw |

|

Excitation force |

120KN |

Total weight |

12T |

|

Pallet size |

1100×900×(12-45)mm |

||

|

Number of molding blocks |

390×190×190mm(10 PCS) |

||

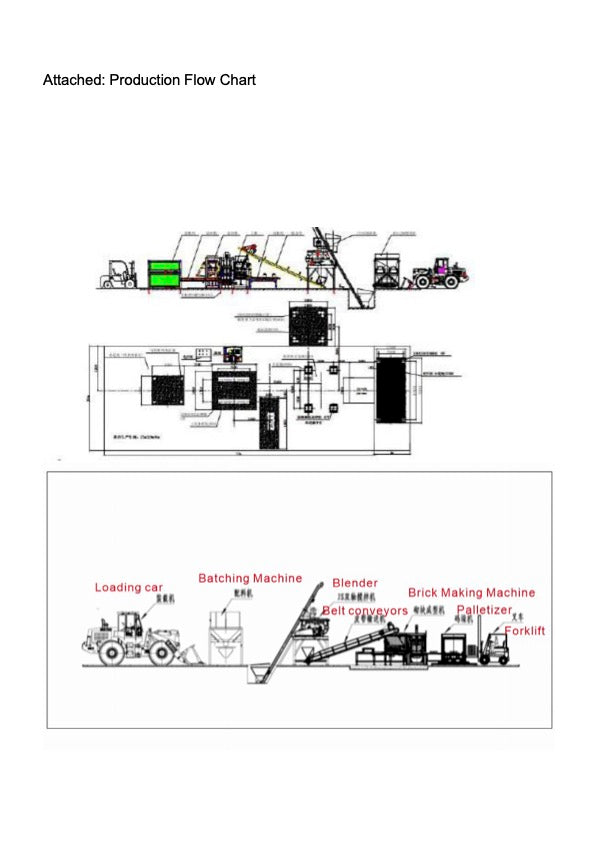

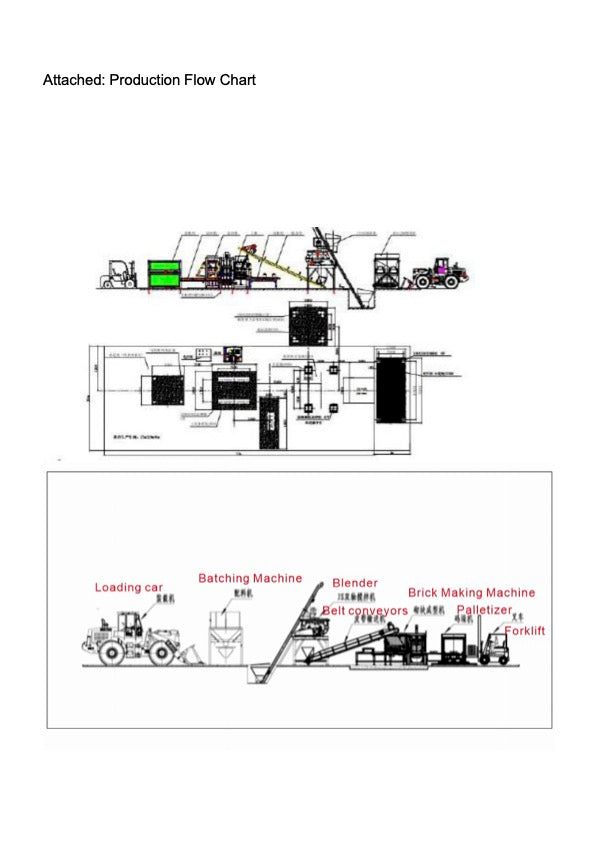

Production process: Loader transports raw materials to batching station → Cement screw sends cement to cement meter → Water pump sends water to water meter → After automatic metering, all materials are mixed and stirred evenly in mixer → Transported to storage bin on main machine through conveyor belt → Storage bin opens and drops the mixture into material box of spreading machine → Spreader spreads the material evenly to mold box → Formed brick blanks are made through the exciting force and pressure of brick making machine → Brick blanks are automatically pushed out → Stacked up by automatic stacking plates on waiting rack (5-10 layers) → Finished brick blanks are transported to site for stacking by forklift → Finished brick blanks can be made into finished bricks after curing for 7-10 days.

Couldn't load pickup availability

Materials

Materials

Shipping & Returns

Shipping & Returns

Dimensions

Dimensions

Care Instructions

Care Instructions

Share