1

/

of

26

Infinity group

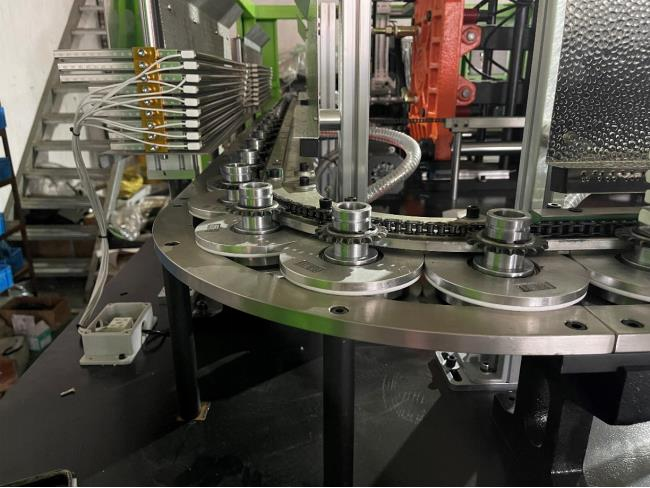

Automatic PET bottle blow molding machine

Automatic PET bottle blow molding machine

Specifications

High-speed Servo Motor PET Bottle Production Line

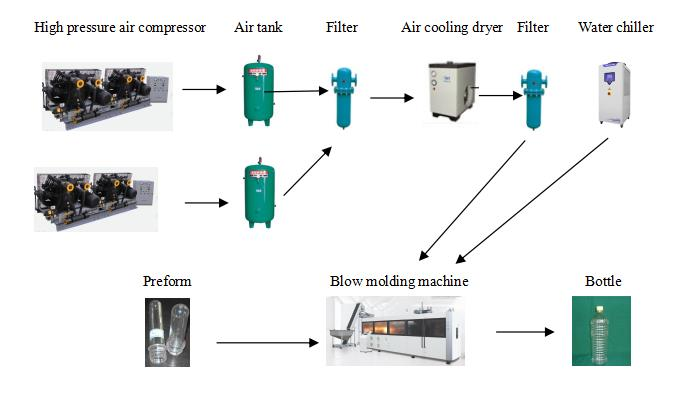

Technological process:

PET Bottle Production Line

High pressure air compressor → Air cooling dryer system → High pressure air tank → Bottle blow molding

machine → Water chiller

Technical parameter:

1. Product specifications/materials: Max. 2L bottle, PET bottle (The size of the sample bottle is based on the

actual product)

2. Overall production capacity: 5,500-6,000 bottles/hour @500ml (speed dependent on bottle capacity)

3. Compressed air consumption: approximately 4.8m3 / 3.0Mpa

4. Floor area: approximately 5.0*2.0m

Auxiliary machines:

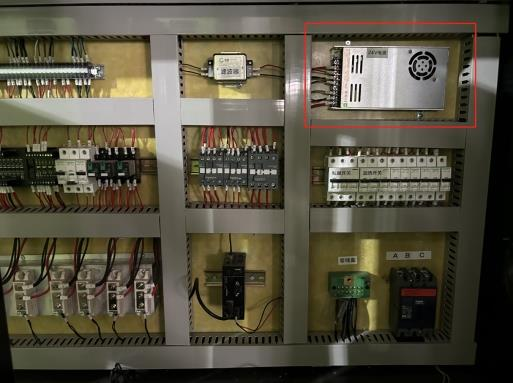

1.High pressure air compressor

Air compressor system, tie-in use combination series high

pressure gas system. Convenient maintenance, easy

inspection and troubleshooting.

2.Aircooling dryer system

Main function is cool high pressure air to achieve a more

ideal working temperature and increase the service life of

pneumatic components and filter theimpurities and oil in the

air, improving product cleanliness.

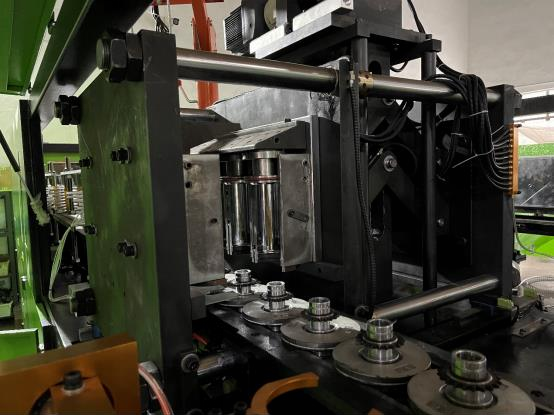

3.Waterchiller

Mainly used for cooling the mould and guarantee the bottle

part not damaged in the heating process, to improve the

quality of finished products and production efficiency.

Regular price

$49,000.00 USD

Regular price

Sale price

$49,000.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Materials

Materials

Shipping & Returns

Shipping & Returns

Dimensions

Dimensions

Care Instructions

Care Instructions

Share